Cov kab ntim khoom noj khoom haus

Lub ntsiab tsis

| Yam khoom | Chav tsev | Parameter | Lus ceeb toom |

| Qauv | FS-FPP75-90 | ||

| Cov ntaub ntawv siv tau | GPPS granules | ||

| Thickness ntawm cov khoom | mm | 1-4 | |

| Dav ntawm daim ntawv | mm | 540–1100 : kuv | |

| Foaming tus nqi | 12-20 | ||

| Qhov hnyav ntawm cov khoom | Kg/m³ | 50-83 : kuv | |

| Thermal conductivity ntawm cov khoom | W/mk | 0.021-0.038 Nws | |

| Tso zis | kg/h | 70-90 ib | |

| Rated zog | Kw | 140 | |

| Fais fab mov | Peb theem 380v / 50Hz | ||

| Sab nraud dimension | mm | 24000 × 6000 × 2800 hli | |

| Ua kom tiav lub tshuab hnyav | Toj | Hais txog 10 |

Ⅰ 75/90 PS ua npuas ncauj extrusion kab suav nrog cov khoom hauv qab no

1. Tsis siv neeg pub mis

1. Pub hom

Kauv noj

2. Cov tsis tseem ceeb

| Hopper muaj peev xwm ntawm tov khoom (kg) | 300 |

|

| Lub cev muaj zog ntawm qhov sib tov (kw) | 3 | |

| Pub muaj peev xwm ntawm feeder (kg / h) | 200 | |

| Lub cev muaj zog ntawm feeder (kw) | 1.5 |

2 Thawj theem extruder

1. Cov khoom siv ntsia hlau thiab lub thoob

38CrMoAlA nitrogen kho

2. Main motor style

AC-lub cev muaj zog nrog zaus converters

⑶ Ceev reducer

Extruder nplooj siab reducer, tawv hniav nto, siab torque, thiab suab nrov tsawg

⑷ Cua sov

Aluminium casted rhaub, solid-state relay contactless tso zis, ntse kub tswj tswj kub

⑸ Technical parameters

| Tsav lub cev muaj zog (kw) | 37 |  |

| Txoj kab uas hla ntawm cov ntsia hlau ntsia hlau (mm) | Φ70 | |

| L / D piv ntawm cov ntsia hlau ntsia hlau | 32:1 ib | |

| Max rev ntawm ntsia hlau (rpm) | 60 | |

| Tus naj npawb ntawm thaj chaw cua sov | 7 | |

| Lub zog cua sov (kw) | 28 |

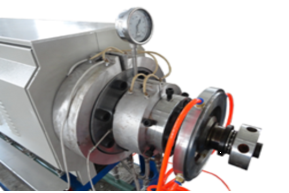

4 Tsis-nres tshuab hydraulic tsis siv neeg hloov lim system

Tsis-nres hydraulic ceev net hloov ntaus ntawv

Lub ntsiab tsis

| Roj twj tso kua mis lub cev muaj zog (kw) | 4 |   |

| Roj twj tso kua mis max siab (Mpa) | 20 | |

| Lim net kom muaj nuj nqis (thooj) | 4 | |

| Lub zog cua sov (kw) |

5 Qhov thib ob theem extruder

1. Cov khoom siv ntsia hlau thiab lub thoob

38CrMoAlA nitrogen kho

2. Main motor style

AC-lub cev muaj zog nrog zaus converters

⑶ Ceev reducer

Extruder nplooj siab reducer, tawv hniav nto, siab torque, thiab suab nrov tsawg

⑷ Cua sov

Aluminium casted rhaub, solid-state relay contactless tso zis, ntse kub tswj tswj kub

⑸ Txias thiab kub-txo style

Circulating dej txias, tsis siv neeg bypass system.

⑹ Technical parameters

| Tsav lub cev muaj zog (kw) | 45 |  |

| Txoj kab uas hla ntawm cov ntsia hlau ntsia hlau (mm) | Φ90 | |

| L / D piv ntawm cov ntsia hlau ntsia hlau | 34:1 ib | |

| Max rev ntawm ntsia hlau (rpm) | 30 | |

| Tus naj npawb ntawm thaj chaw cua sov | 8 | |

| Lub zog cua sov (kw) | 40 |

6 Extruder taub hau thiab pwm

1. Qauv

Round ntawm lub taub hau extruder, pwm lub qhov ncauj tuaj yeem kho tau, lub taub hau nrog lub ntsuas siab thiab lub tswb nrov tso tawm.Lub taub hau rhaub nrog dej txias.

2. Khoom siv

Qhov siab: 0.025μm

Cov cuab yeej zoo hlau, kub-kho, ntws channel nto roughness: Ra0.025μm

⑶ Cov ntaub ntawv tseem ceeb

| Txoj kab uas hla ntawm pwm orifice | raws li daim ntawv cog lus |  |

| Ntau qhov chaw tswj qhov kub thiab txias | 2 | |

| Kev tswj qhov kub thiab txias (℃) | ± 1 | |

| Lub zog cua sov (kw) | 5 |

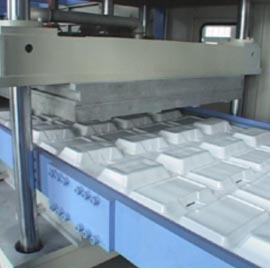

7 Shaping txias thiab txiav system

1. Shaping style: shaping chim

2. Txias style: shaping chim txias nrog dej thiab sab nraud cua-ntiv nplhaib

⑶Structure: shaping chim, txiav riam thiab khib Cheebtsam

⑷ Main technical parameters

| Shaping chim loj (mm) | Raws li daim ntawv cog lus |  |

| Lub cev muaj zog (kw) | 3 nqe 0.55 |

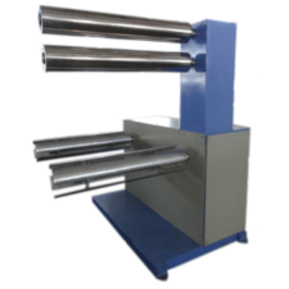

8 Pulling system

1. Pulling style: plaub-roller parallel rub

2. Tsav tsheb daim ntawv: AC-lub cev muaj zog, zaus hloov dua siab tshiab kev hloov pauv, ceev reducer hloov ceev

⑶ Lub ntsiab tsis muaj

| Rub cov menyuam kom muaj nuj nqis (thooj) | 4 |  |

| Rub cov menyuam loj (mm) | Φ260 × 1300 | |

| Lub cev muaj zog (kw) | 1.5 |

9 Electrostatic tshem tawm qhov system

| Txais tos rau tod hom ion pas nrig electrostatic tshem tawm qhov system, ua haujlwm volt yog 7KV saum toj no, tuaj yeem tsim tau zoo thiab muaj zog ion cua, tshem tawm electrostatic txaus ntshai. |  |

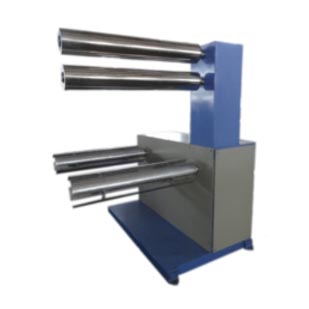

10 Winding system

1. Daim ntawv

Ob chav caj npab cua ncej hom

2. Cov yam ntxwv tseem ceeb

| Coiling hnyav (kg) | Ntau tshaj 40 |  |

| Coiling txoj kab uas hla (mm) | Max 1100 | |

| Ntev tswj | Meter txee tswj, kho qhov ntev | |

| Tsav lub cev muaj zog | Lub cev muaj zog 8n.m × 4sets |

11 Hluav taws xob tswj qhov system

| extruder cua sov tswj txee | Ib txheej |   |

| Qhov thib ob theem extruder cua sov tswj txee | Ib txheej | |

| winding tswj txee | Ib txheej |

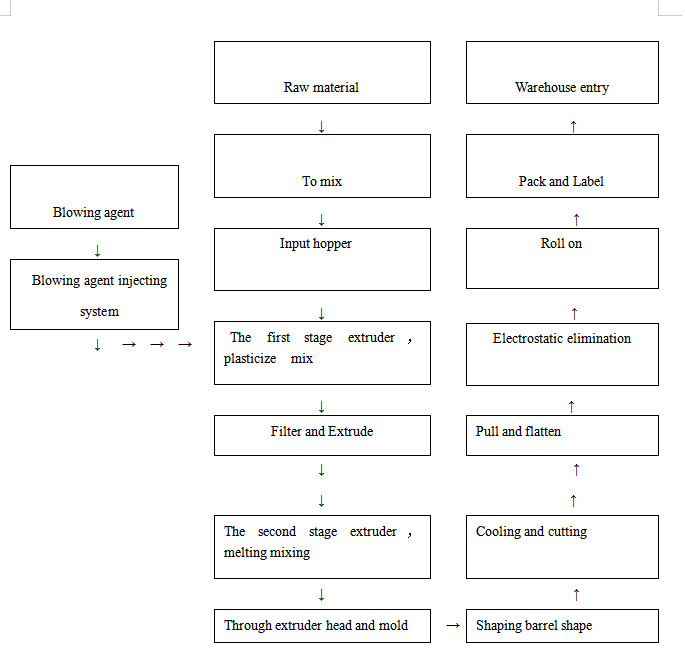

Ⅲ Ntau lawm flow chart

Ⅳ Cov ntsiab lus ntawm cov ntawv ua npuas ncauj extrusion kab

A. Tsis siv neeg pub mis

1. Pub hom

Kauv noj

2. Cov tsis tseem ceeb

| Hopper muaj peev xwm ntawm tov khoom (kg) | 300 |

| Lub cev muaj zog ntawm qhov sib tov (kw) | 3 |

| Pub muaj peev xwm ntawm feeder (kg / h) | 200 |

| Lub cev muaj zog ntawm feeder (kw) | 1.5 |

B. Thawj theem extruder

1.Screw thiab chim khoom

38CrMoAlA nitrogen kho

2. Main motor style

AC-lub cev muaj zog nrog zaus converters

3. Ceev reducer

Extruder nplooj siab reducer, tawv hniav nto, siab torque, thiab suab nrov tsawg

4. Cua sov

Aluminium casted rhaub, solid-state relay contactless tso zis, ntse kub tswj tswj kub

5. Technical parameters

| Tsav lub cev muaj zog (kw) | 37 |

| Txoj kab uas hla ntawm cov ntsia hlau ntsia hlau (mm) | Φ70 |

| L / D piv ntawm cov ntsia hlau ntsia hlau | 32:1 ib |

| Max rev ntawm ntsia hlau (rpm) | 50 |

| Tus naj npawb ntawm thaj chaw cua sov | 7 |

| Lub zog cua sov (kw) | 28 |

C. Tshuab tshuab txhaj tshuaj system

1. Hom twj tso kua mis

Plunger hom siab precision thiab siab ntsuas twj tso kua mis, kom phim ib txoj kev valve los tswj, lub ntim ntim yog tswj los ntawm plunger nqa

2. Cov yam ntxwv tseem ceeb

| Hom tshuab tshuab | butane los yog LPG |

| Metering twj tso kua mis | 40 (L / H) |

| Txhaj tshuaj siab | 30 (Mpa) |

| Siab ntsuas | 0-40 (Mpa) |

| Lub cev muaj zog | 3 (kw) |

D. Tsis siv neeg nres tshuab hydraulic tsis siv neeg hloov lim system

Hydraulic ceev ceev net hloov ntaus ntawv

Lub ntsiab tsis

| Roj twj tso kua mis lub cev muaj zog | 4 (kw) |

| Roj twj tso kua mis max siab | 20 (Mpa) |

| Lim net kom muaj nuj nqis | 4 (pcs) |

| Lub zog cua sov | 8 (kw) |

E. Qhov thib ob theem extruder

1. Cov khoom siv ntsia hlau thiab lub thoob

38CrMoAlA nitrogen kho

2. Main motor style

AC-lub cev muaj zog nrog zaus converters

3. Ceev reducer

Extruder nplooj siab reducer, tawv hniav nto, siab torque, thiab suab nrov tsawg

4. Cua sov

Aluminium casted rhaub, solid-state relay contactless tso zis, ntse tswj kub tswj kub, txias dej ntaus ntawv nyob rau hauv lub rhaub.

5. Txias thiab kub-txo style

Circulating dej txias, tsis siv neeg bypass system.

6. Technical parameters

| Tsav lub cev muaj zog (kw) | 45 |

| Txoj kab uas hla ntawm cov ntsia hlau ntsia hlau (mm) | Φ120 |

| L / D piv ntawm cov ntsia hlau ntsia hlau | 34:1 ib |

| Max rev ntawm ntsia hlau (rpm) | 50 |

| Tus naj npawb ntawm thaj chaw cua sov | 8 |

| Lub zog cua sov (kw) | 40 |

F . Extruder taub hau thiab pwm

1. Qauv

Round ntawm lub taub hau extruder, pwm lub qhov ncauj tuaj yeem kho tau, lub taub hau nrog lub ntsuas siab thiab lub tswb nrov tso tawm.Lub taub hau rhaub nrog dej txias.

2. Khoom Ra0.025μm:

Cov cuab yeej zoo hlau, kub-kho, ntws channel nto roughness: Ra0.025μm

3. Cov ntaub ntawv tseem ceeb

| Txoj kab uas hla ntawm pwm orifice | Raws li daim ntawv cog lus |

| Ntau qhov chaw tswj qhov kub thiab txias | 1 |

| Kev tswj qhov kub thiab txias | ± 1 (℃) |

| Lub zog cua sov | 5 (kw) |

G. Shaping txias thiab txiav system

1. Shaping style: shaping chim

2. Txias style: shaping chim txias nrog dej thiab sab nraud cua-ntiv nplhaib

3.Structure: shaping chim, txiav riam thiab khib Cheebtsam

4. Cov yam ntxwv tseem ceeb

| Shaping chim loj (mm) | Raws li daim ntawv cog lus |

| Lub cev muaj zog (kw) | 3 nqe 0.55 |

H. Pulling system

1.Pulling style: plaub-roller parallel rub, compress nrog cua tsav

2. Tsav lub cev muaj zog daim ntawv: AC-lub cev muaj zog, zaus hloov dua siab tshiab kev hloov pauv, ceev reducer hloov ceev

3. Cov tsis tseem ceeb

| Rub cov menyuam kom muaj nuj nqis (thooj) | 4 |

| Rub cov menyuam loj (mm) | Φ260 × 1300 |

| Lub cev muaj zog (kw) | 1.5 |

I. Electrostatic tshem tawm qhov system

Txais tos rau tod hom ion pas nrig electrostatic tshem tawm qhov system, ua haujlwm volt yog 7KV saum toj no, tuaj yeem tsim tau zoo thiab muaj zog ion cua, tshem tawm electrostatic txaus ntshai.

J. Winding system

1. Daim ntawv

Ob chav caj npab cua ncej hom

2. Cov yam ntxwv tseem ceeb

| Coiling hnyav (kg) | Ntau tshaj 40 |

| Coiling txoj kab uas hla (mm) | Max 1100 |

| Ntev tswj | Meter txee tswj, kho qhov ntev |

| Tsav lub cev muaj zog | Lub cev muaj zog 8n.m × 2 teev |

K. Hluav taws xob tswj qhov system

Cua sov tswj txee ntawm thawj theem extruder: ib txheej

Cua sov tswj txee ntawm theem ob extruder: ib txheej

Winding tswj txee: ib txheej